Nanosolar FAQ

General

When was Nanosolar founded?

Nanosolar was founded in 2002, with a focus on developing low-cost manufacturing processes for solar energy solutions.

What does Nanosolar do?

Nanosolar Inc. designs, engineers and manufactures innovative thin film solar cells and panels based on printing CIGS (Copper, Indium, Gallium, Selenium) and proprietary inks on aluminum foil.

Where is Nanosolar located?

Nanosolar’s headquarters in San Jose, California. The company has a 200,000 square feet solar cell printing factory in San Jose and a 500,000 square feet panel-assembly factory in Luckenwalde, Germany.

Who is on Nanosolar’s management team?

- Karl Steigele – President & Chief Operating Officer

- Ravi Balaji – Vice President, Cell Operations

- John Bender – Vice President, Supply Chain

- Mirco Boldt – Vice President, Panel Operations and Managing Director Nanosolar GmbH

- Dave Jackrel – Vice President, Research and Development

- Roy Shaw – Head, North America Sales

- David Wilson – Chief Financial Officer

- Stefan Zschiegner – Vice President, Global Marketing and Product Development

Who is on the Nanosolar Board of Directors?

- Guido Polko – Executive Chairman of the Board

- Karl Steigele – Chief Executive Officer

- Rhea J. Hamilton– Executive Director, aeris CAPITAL

- Erik Oldekop – Executive Director, aeris CAPITAL

Who has invested in Nanosolar?

The company is backed by leading cleantech investors and renewable energy generators including aeris CAPITAL, Arsenal Venture Partners (via its OnPoint Technologies fund), Mohr Davidow Ventures, Benchmark Capital, Ohana Holdings, Advanced Energy Systems (AES), Everest Group, EDF Energy and Energy Capital.

In addition, Nanosolar has received $35 million in research and development grants from the U.S. Department of Energy and a $10.3 million Defense Advanced Research Projects Agency (DARPA) R&D contract.

What products does Nanosolar make?

Nanosolar manufactures high efficiency, CIGS solar cells based on ink deposition techniques and industrial coating processes. Combined with a multi-functional module factory, we are able to build a variety of products. Currently, Nanosolar has certified its Utility Panel, which is a glass/glass solar module for ground mount installations, and is working to certify our next generation UltraLight solar module. The UltraLight is a light weight solar module uniquely designed to enable BIPV for commercial rooftops, FIPV for expeditionary uses and VIPV for transportation.

Who are Nanosolar’s customers?

Please see our Installation Map on our website for more details on projects and customers.

Does Nanosolar have its own manufacturing plant?

Yes. Nanosolar opened the industry’s first roll-to-roll solar cell printing factory in San Jose, California, and has a panel-assembly factory in Luckenwalde, Germany.

What industry accolades have been received by Nanosolar?

Nanosolar was named Popular Science’s top Innovation of the Year in 2007, and listed in Time Magazine’s 50 Best Inventions of the Year in 2008. The company also was awarded the Conservation Champion Award from U.S. Senator Barbara Boxer.

Technology

What makes Nanosolar unique?

By printing proprietary CIGS inks on low-cost aluminum foil, Nanosolar is utilizing its proprietary high-throughput roll-to-roll printable semiconductor technology to enable the world’s lowest-cost thin-film solar panels. This approach minimizes the use of expensive, high vacuum manufacturing equipment, and enables Nanosolar solar cells and panels to reach efficiencies competitive with crystalline silicon panels.

The pioneering design of the Nanosolar Utility Panels is designed to reduce balance-of-system costs through less mounting hardware, electrical cabling and installation labor.

The combination of Nanosolar’s proprietary CIGS printing technology and panel design results in a lower levelized cost of energy (LCOE) compared to competing solar technologies. Printed CIGS typically has cost advantages over other vacuum-based methods of depositing thin film solar cell materials (e.g. sputtering), such as lower equipment costs, and much higher material utilization.

Moreover, Nanosolar’s new proprietary, next-generation CIGS technology platform, Print2Power™, enables our technology roadmap to increase power conversion efficiencies to 16 percent and beyond eventually matching if not potentially surpassing current c-Si efficiency rates, while reducing total costs and enabling new applications.

Nanosolar’s technology is protected by 54 U.S. and international patents issued and more than 300 applications.

What is CIGS?

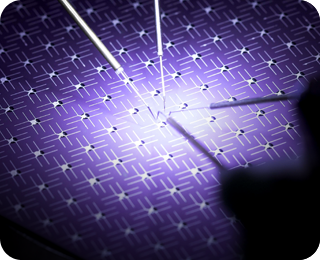

Copper indium gallium (di)selenide (CIGS) is a I-III-VI2 semiconductor material composed of copper, indium, gallium, and selenium. Nanosolar has created a unique industrial printing process to coat aluminum foil with proprietary CIGS inks. Nanosolar created this process, using custom-built equipment to print the ink on rolls of aluminum foil. This ‘roll-to-roll processing’ is a fast inexpensive manufacturing technique compared to conventional processing of glass plates using slow and expensive high vacuum equipment.

In addition to printing the CIGS layer, there are other heating and chemical processing steps using custom-built equipment to create working solar cells. Every step is done in a continuous fashion, and at the end of the process a single roll is essentially a single solar cell with an area of more than 1 square kilometer! At the last step, the continuous foil is cut into individual cells, which can be connected in a variety of ways to create Nanosolar Utility Panels. Nanosolar’s solar cells can be of any size.

Nanosolar has achieved 17.1% efficiency on laboratory devices, certified by the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL), which shows the potential of our technology to compete with the efficiency of crystalline silicon panels in the next several years.

Why is CIGS important?

CIGS is a promising light absorber material for thin-film solar cells and an alternative to crystalline silicon (c-Si) based technology. CIGS solar cells are capable of offering the highest efficiencies of all thin-film technologies on laboratory scale and demonstrate higher energy yield (PR) than comparable c-Si technologies. This enables CIGS to provide competitive LCOE and attractive project returns at lower conversion efficiency representing an attractive alternative in existing markets. Additionally, CIGS technology has inherent attributes that provide the potential for new applications in new markets, e.g. light weight roofing, and/or flexible transportation- and BIPV applications.

How efficient is CIGS technology?

Nanosolar CIGS has proven its efficiency in a number of third-party laboratory tests:

- 2009 – National Renewable Energy Laboratory (NREL) independently verified several of Nanosolar’s cell lab foils to be as efficient as 15.3 percent.

- April 2011 – Nanosolar announced new efficiency benchmarks of 11.6 percent for the Nanosolar Utility Panel and 13.9 percent for its printed CIGS solar cells, as measured by the Fraunhofer Institute for Solar Energy (ISE) and NREL.

- October 2011 – Nanosolar achieved 17.1 percent aperture efficiency.

Where are Nanosolar’s current deployments?

Please see our Installation Map on our website for more details on each project.

Where will Nanosolar systems be the most efficient?

Our panels perform best in high irradiance locations with high levels of direct sunlight. Ideal markets for this technology include the Mediterranean (Spain, Italy, Greece), the Southwest US (California, Nevada, Arizona, New Mexico, Texas, Colorado), Australia, Mexico, North Africa, the Middle East, as well as other areas in the southern hemisphere.

What are Nanosolar’s efforts to minimize its environmental impact?

We continually strive to reduce the environmental impact of our research, development and engineering processes, and the carbon footprint of the solar cells and panels we manufacture.

The end-to-end lifecycle footprint of a Nanosolar Utility Panel is among the lowest in the solar industry for both carbon dioxide and toxic emissions, and the energy payback time of our solar cells and panels is less than eight months. Nanosolar is also committed to recycling both office and manufacturing waste at all of our facilities.

Nanosolar is a member of PV Cycle, the European organization committed to responsibly recycle solar panels.

What is LCOE?

There are a number of ways to measure the relevant costs affiliated with generating that kWh of electricity purchased by consumers, be it residential, commercial or industrial – but one most commonly used method involves measuring the “levelized cost of energy” (LCOE). It examines the costs –excluding the effects of any subsidies or support mechanism- associated with generating clean energy from various technologies. LCOE seeks to take into account all projects costs and financial assumptions over the lifetime of a project.

What’s the meaning of all these energy-related terms?

The U.S. Department Energy offers its comprehensive glossary of terms here and this quick table sums up what we are referencing on our site and documentation.

| Watt: | Unit of power |

| KW (kilowatts): | 1000 Watts |

| MW (megawatt): | One Million Watts (106) |

| GW (gigawatt): | One Billion Watts (109) |

| TW (terawatt): | One Trillion Watts (1012) |