Production Process

Geared to Enable Lowest Total Costs

Nanosolar grows a thin film semiconductor using a printing and annealing process that is far faster than conventional high vacuum deposition. We leverage the latest advances in nanoscience to create high quality, highly uniform layers of nanoparticles dispersed through our proprietary CIGS ink. This allows us to utilize equipment from the industrial printing and roll-to-roll manufacturing industries to produce solar-electric foil at high speeds, bringing the economics of printing to the world of solar PV semiconductor manufacturing.

Each of our production steps is geared towards achieving high intrinsic throughput so that we can produce solar cells and panels with superior cost and capital efficiency:

Nanoparticle Ink

Nanosolar has developed a proprietary ink formula and techniques for fabricating our nanoparticles that are non-agglomerating and that produce high-quality coatings.

Printed Foil

The nanoparticle ink is printed onto a specially prepared proprietary aluminum metal foil using high-throughput industrial printing techniques that work in normal atmosphere, with no cleanroom required.

Cell Formation

The resulting two kilometer long roll of solar cells is completed by adding fingers and a back contact capable of efficiently carrying high current with minimal optical and resistive loss. The solar-electric foil is then slit and sheeted into pieces to form individual solar cells. Cells are individually tested and sorted into performance bins based on electrically matched characteristics.

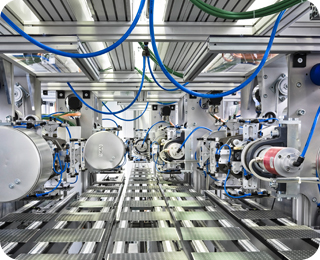

Panel Assembly

Panel Assembly

Applying the latest in high-throughput robotic manufacturing–primarily from the automotive industry–Nanosolar assembles solar cells into high-quality solar panels. Cells are interconnected into series circuits and laminated into solar panels. By using cells from matched performance bins, losses within a panel are minimized to improve field panel performance and reliability.

Consistent inspections, manufacturing process control and on-going testing are a critical part of Nanosolar’s production quality. Our process culminates in a cost-efficient solar panel that is guaranteed for twenty-five years.